Warning: Undefined variable $videoThumbnails in /www/www10/htdocs/blogs/wp-content/themes/ibs_home/weekly.php on line 166

Warning: foreach() argument must be of type array|object, null given in /www/www10/htdocs/blogs/wp-content/themes/ibs_home/weekly.php on line 166

Warning: Undefined variable $videoThumbnails in /www/www10/htdocs/blogs/wp-content/themes/ibs_home/weekly.php on line 166

Warning: foreach() argument must be of type array|object, null given in /www/www10/htdocs/blogs/wp-content/themes/ibs_home/weekly.php on line 166

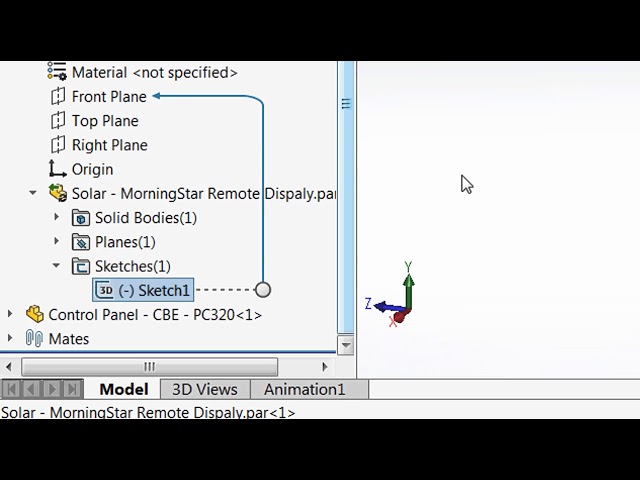

One way to increase assembly performance is by using simplified configurations that can be selected when opening an assembly. Simplified configurations reduce the amount of data that must be loaded into RAM which increases graphical performance by requiring fewer edges and details to be displayed. When simplifying components general guidelines are useful for determining what can be removed and what is important to retain.

It’s 2018, and along with being cloud based, virtually every engineering design software company has embraced the inevitability of the Internet of Things (IoT) – some better than others. SOLIDWORKS is no exception, as it announced an add-in with Seebo that will enhance its IoT presence through connected products.

Today’s manufacturers are increasingly turning to IoT to meet strategic business objectives – from improving product resilience and efficiency, to growing sales, and boosting customer satisfaction.

However, the high-rate of stalled and failed IoT initiatives – which, according to a recent Cisco study, account for a whopping 75% – continues to reflect how IoT development remains complicated, expensive, and risky.

Product teams turn to companies like Seebo to visually describe their connected products in a digital model. The Seebo platform then automatically generates the specs, simulations, and analytics to make it happen.

At the SOLIDWORKS World 2018 Conference, Seebo announced a SOLIDWORKS add-in for manufacturers to plan and deliver smart, connected products. As a new certified Gold Partner for SOLIDWORKS, Seebo launched the add-in for SOLIDWORKS users to turn their existing 3D product designs into a visual model of the entire IoT system, and get auto-generated specs, simulations, and analytics to make their products IoT connected.

Seebo and SOLIDWORKS For Planning And Delivering IoT Products

The Seebo add-in for SOLIDWORKS addresses the pains of planning and delivering IoT products. With Seebo, SOLIDWORKS users are equipped with tools for IoT modeling, simulation, execution, and behavior analytics. This allows them to quickly and easily define, validate, and build IoT products. Once in-market, product teams see exactly how their product is being used and make informed data-driven decisions about product enhancements to boost product adoption and profits.

“Mastering how to design for the Internet of Things will be one of the major challenges for companies in the next 2-3 years,” said Kishore Boyalakuntla, VP of Product Portfolio Management, SOLIDWORKS, Dassault Systèmes. “The Seebo add-in helps users seamlessly turn their existing SOLIDWORKS designs into connected products that drive outstanding customer value.”

Lior Akavia, Seebo Co-Founder and CEO said, “We are excited to be a certified Gold Partner for SOLIDWORKS, making IoT design accessible and simple to the millions of SOLIDWORKS users worldwide. Equipped with the Seebo add-in, users will be able to launch products that stand out from the competition and boost customer satisfaction with innovative capabilities, superior performance, and minimized downtime.”

According to VP of Product Portfolio Management at Dassault Systèmes SOLIDWORKS, Kishore Boyalakuntla, among the leading challenges companies are facing is “mastering how to design for the Internet of Things.”

To address these pains, SOLIDWORKS has teamed up with Seebo to make IoT design accessible to SOLIDWORKS.

With Seebo, SOLIDWORKS users have tools for IoT Modeling, Simulation, Execution, and Behavior Analytics. This allows them to quickly define, validate, and build IoT products. Once in-market, product teams see exactly how their product is being used and make informed data-driven decisions about product enhancements to boost product adoption and profits.

It takes just a few hours for SOLIDWORKS users to turn their existing 3D product designs into a visual model of the entire IoT system on Seebo’s platform. Inside Seebo, users get auto-generated specs, simulations, and behavior analytics to make their products IoT connected.

Lior Akavia, CEO of Seebo, Delivers Keynote Address At SOLIDWORKS WORLD 2018 Announcing The Partnership Between Seebo And SOLIDWORKS

The Seebo add-in for SOLIDWORKS is available in a controlled release, and SOLIDWORKS users can register for a free trial at seebo.com/solidworks.